|

You know you’re nearing the end of a build when all your body components finally have the final finish on them whether it is powder coat or paint. In our case it’s both. Throughout this build we have been periodically sending our completed parts next door to Jason Fritz at Protek Powder Coaters to get some color laid down. Well, this week we got our final parts back from Jason and can now see the light at the end of the tunnel. We started with installing the turn signal and marker lights on our front fenders as well as a washer fluid tank and the coolant reservoir tank. Mounting the front fenders back on the truck was super easy and this is when we can start mounting the rest of our engine bay goodies like our front grill and bezel. We get to install the additional marker lights and headlights and of course the hood. Another product we manufacture here in house is our fiberglass hard tops for the FJ45 Cab. We got ours back from paint and the color match is perfect! Before we mounted the hardtop to the Cab we sprayed in some bed liner to finish it off on the inside. We also sprayed the inside of the box with the same bed liner. Next week we will be reattaching everything back to the truck. Hook up some full lines, fill all the fluids and hopefully hear this thing running! *Disclaimer, Aqualu only builds vehicles for in house abuse, we do not offer build services.*

1 Comment

After fitting the box to our powder coated frame last week. We have since prepped it by blocking out the aluminum and grinding down any visible welds then sent it next door to have powder coated to match the cab. This week we have been busy building as much of our cab off the frame as we can before laying it on the frame for a final time. We are installing things like our gauges, brake booster and steering column. Getting the roll bar to fit back in without scratching any of the powder coat was a challenge but with a few heavy duty ratchet straps we managed to squeeze it back into place. The cab went together pretty smoothly and now we can get it on our frame. Now that our cab is on the frame we can fit our other front end components for final fit up before we send them to get some color as well. We had to widen our #4023 extra wide front fenders an additional 4” to get the tire coverage to match the rear. The idea now is to adjust everything up front in order to get even gaps all around making sure the pieces are centered and level. Taking your time with this step will ensure we get a super nice finished product. After a few hours of adjusting all the front end components we were happy with the results, and it could all be taken apart again to be prepped for powder coating. We are getting close to finalizing this build and I for one am getting antsy to hear it come to life. *Disclaimer, Aqualu only builds vehicles for in house abuse, we do not offer build services.*

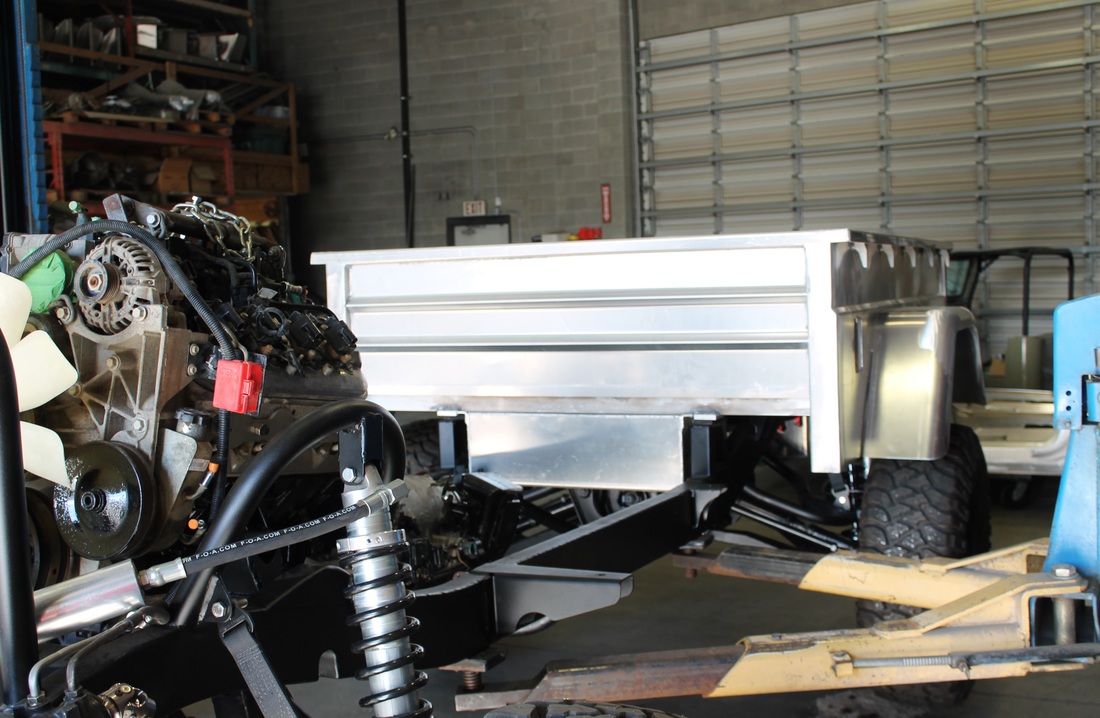

The last time we fit our box on the frame we noticed the wheels were way too wide and we had zero coverage which is something we needed to address. What we have done is taken the design of our #4038 rear fender flares – large and widened them another 4 inches and changed our wheel choice to something with a lot less of an offset. Changing the wheels netted us approximately 7 inches of total width overall and with the addition of the wider fender flares we now have almost 100% tire coverage. If we were building another snow thrower, we wouldn’t have worried so much about the coverage but we also need this thing to be streetable. After we mounted the box to the frame, installed the tailgate and our custom fender flares we needed to make sure we could flex it out without the tires interfering with our box. If any modifications were to be made, now is the time because in a couple weeks it is getting powder coated. The F-O-A coilover’s definitely kept the tires far away from the box and the fender flares. I don’t think we will have any issues tackling any terrain from the local trails to the street in any weather. As you can see we have also made pretty good progress on mounting our drive train. The 6.0ltre LQ4 and 4L80e transmission are in their final resting places. Next week we will be throwing some color on the cab and piecing it together so stay tuned. *Disclaimer, Aqualu only builds vehicles for in house abuse, we do not offer build services.*

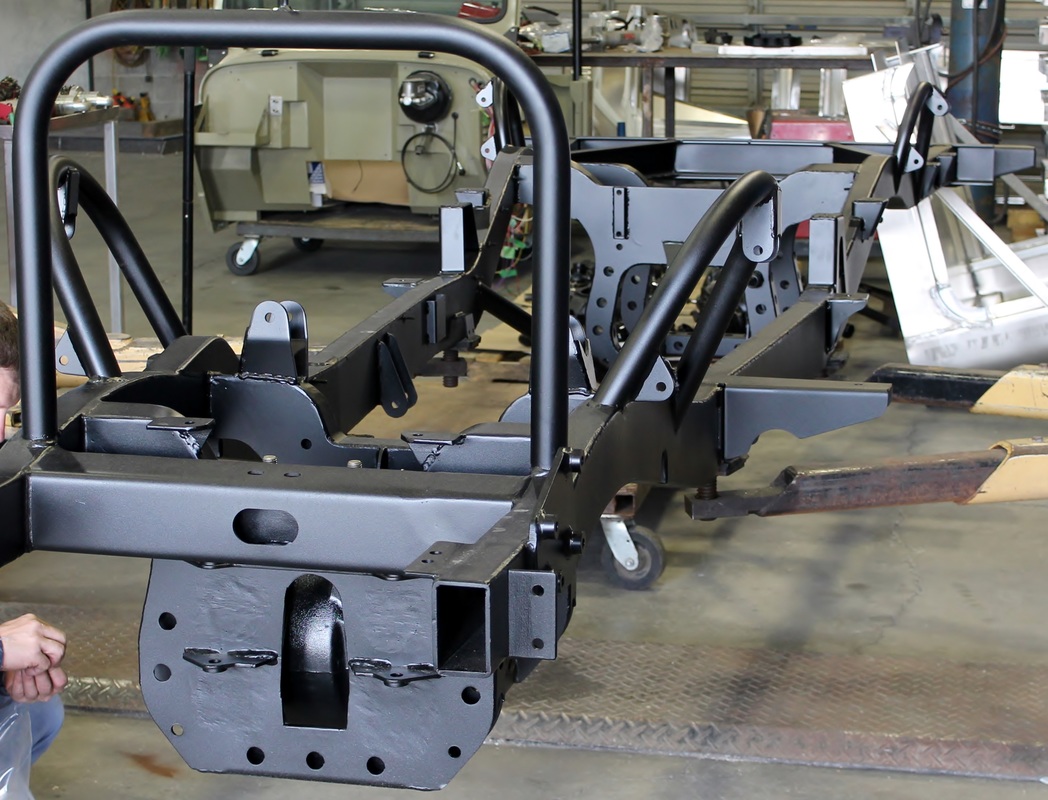

Well, we have finally come to the disassembly point in our build. Kind of an oxymoron really but were getting everything ready for powder coating. AQUALU HIGHLY RECOMMENDS YOU PRE-FIT ALL YOUR COMPONENTS PRIOR TO PAINTING OR POWDER COATING. We have received a lot of questions throughout the years in regards to painting or powder coating one of our tubs, so I will fill you in on what our customers have done in the past. Powder coating is the easiest, once you have pre-fit everything and are ready for some color, Block out and prep your tub and send them off to the powder coaters. With this method, there will most likely be some minor imperfections visible through the powder coat. For a more show room finish, some of our customers told us that they have used the powder coat as a primer base then sanded and prepped for a top coat finish. If you want to go straight to a body shop to have them lay down some automotive paint, we recommend starting with a coat of etching primer, then your high build primer before moving onto laying down some paint. Or you can simply Sand and polish our tubs for a mirror finish. Whichever method you chose to go with when it comes to putting some color on one of our tubs, one thing will always remain the same; a paint job is only as good as the prep work. For our frame, we sent it off to have it sandblasted. 2 days later it was ready for us to go pick it up. Before sending it to get powder coated we had a few last minute items that needed addressing and of course more prep work. Jason Fritz at Protek Powder Coating helped us out again when our frame was ready for some color. We chose to go with a textured black for our chassis and as our accent color for most of our accessories on the truck. Nothing too flashy but it provides a great contrast against the color we chose for our truck. It wasn’t long before we had our Frame back from Jason and we could start piecing it all together again for the last time. *Disclaimer, Aqualu only builds vehicles for in house abuse, we do not offer build services.*

|

AuthorArchives

January 2017

Categories |

Serving the Off-Road Community since 1989.

Get Updates from Aqualu |

Aqualu Industries Inc.

|

Aqualu Industries Inc. | Content Copyright © 2024

RSS Feed

RSS Feed