|

This week was busy, we are swamped filling out orders for aluminum FJ40 bodies, all kinds of jeep bodies and not to mention all the accompanying accessories. However, throughout the intense work schedule we still managed to find time to fit the cab onto the frame. It was straight forward and fit together seamlessly like jeep ownership and an empty bank account. This is to be expected when you manufacture both the bodies and the frames. When fitting the body there were a few custom touches we needed to work around like the disk style parking brake and the 4L80e tranny so there were a few times we had to take the cab back off for more clearance. Once the cab and cowl found its final resting spot we were able to start locating everything on the firewall like our Wilwood master cylinder, heater hose location and our battery box. On the dash we went with Auto meter gauges for a speedometer, RPM gauge and fuel level. In the center of the dash we have an oil pressure gauge, Volt meter and water temperature also from Auto meter. Ignition switch, headlights, wipers and various other switches were also installed. Once everything was in its place we then tore it all out and took the Cab off of the frame for the last time. We ground down certain welds and prepped the cab and cowl to send it off for powder coating. Remember, Aqualu highly recommends pre fitting all components prior to painting or powder coating. We took the cab and cowl next door to our friend Jason Fritz, General Manager of Protek Powder Coaters in Kelowna B.C. Jason and his crew completed any necessary prep work prior to loading it in the spray booth. We’re excited to see this start to get some color to it. *Disclaimer, Aqualu only builds vehicles for in house abuse, we do not offer build services.*

2 Comments

Powering our little project truck dubbed ‘The Shop Truck’ is a GM LQ4 6.0 litre engine. We snagged this motor for a song from a friend of ours who had a 2006 Chevy ¾ ton 4x4 truck sitting in his yard. It had higher mileage on it but it ran smooth and idled nicely so we couldn’t pass it up. The engine itself is bone stock and we plan on keeping it that way to keep up with the reliability we require out of this rig as we plan on making it a street-able monster. To go with all of our other custom built components on this rig, to clear the frame rails, our shock hoops and the firewall of the truck, we went ahead and fabbed up our own headers to ensure we get the clearance we need. Behind the 6.0 litre we also kept the stock GM 4L80e automatic tranny from the same donor vehicle. The 4L80e is a great 4 speed tranny with overdrive for everyday use as it is the evolutionary step up from the popular TH400. We weren’t as lucky with the tranny as we were with how well the engine ran, so we took it over to Ivar, owner of Kelowna Transmission and auto repair just down the street for a complete rebuild. When it comes to Transfer-case choices the options can be as vast and as deep as your pockets will allow. We thought about putting in an Atlas II like we did on our ‘Grey Cruiser’ but we feel that dollar for dollar, pound for pound, the best transfer case out there for our application was going to be the robust NP205. With a factory low gear of 1.96:1 it may not be the best set up for rock crawling right now but with a little aftermarket support we could get that down to a 3.00:1 low range, but for now, we will keep the factory gearing to maintain its street manners. A couple of custom mounts and a cross member later, the drivetrain is in and looks right at home in our ‘Shop Truck’. *Disclaimer, Aqualu only builds vehicles for in house abuse, we do not offer build services.*

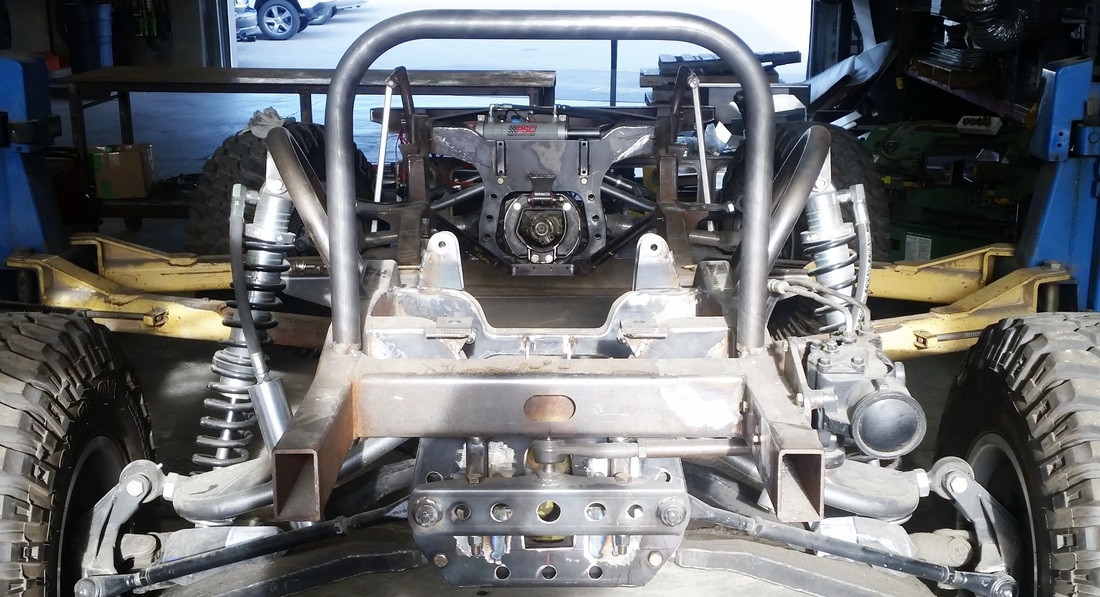

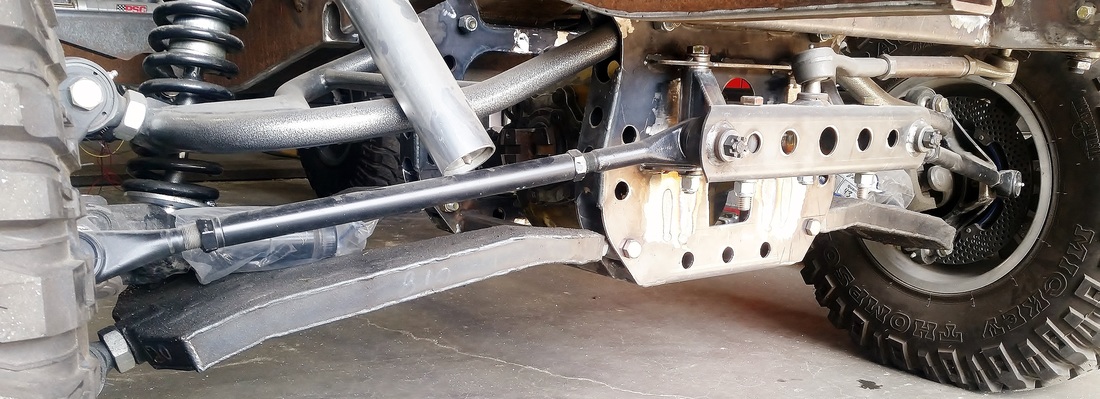

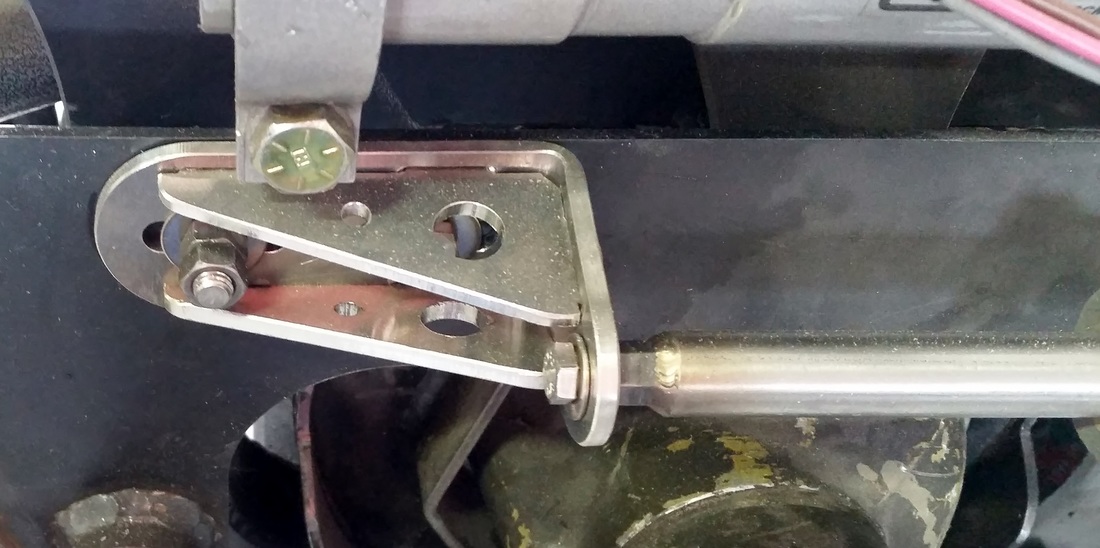

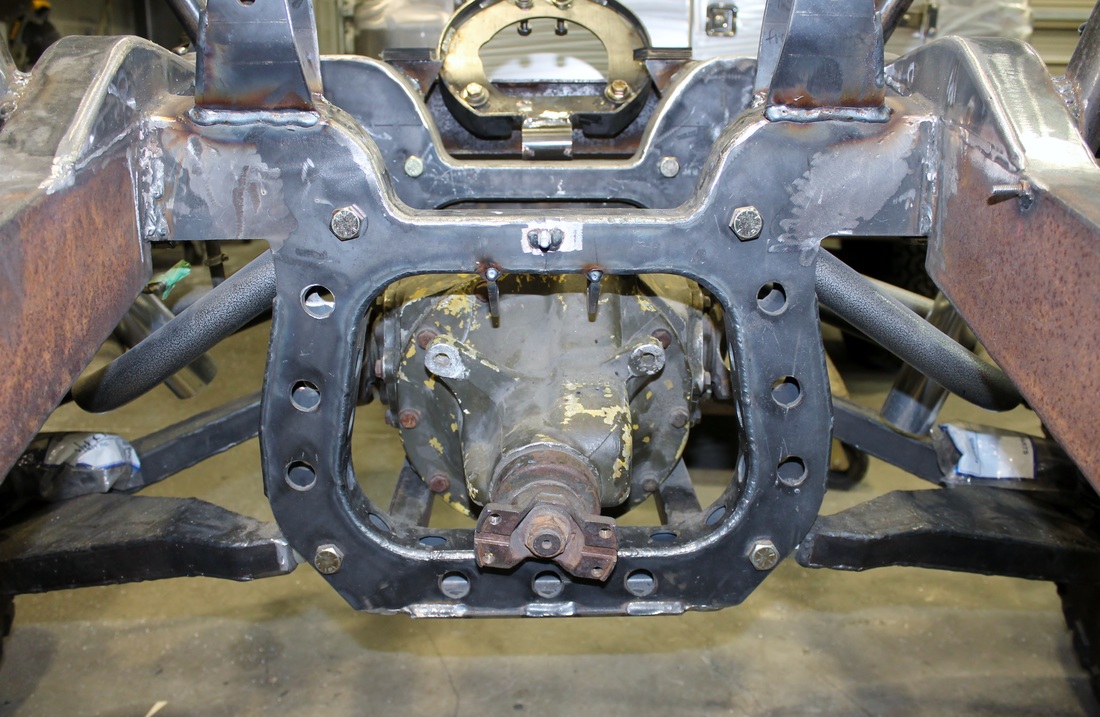

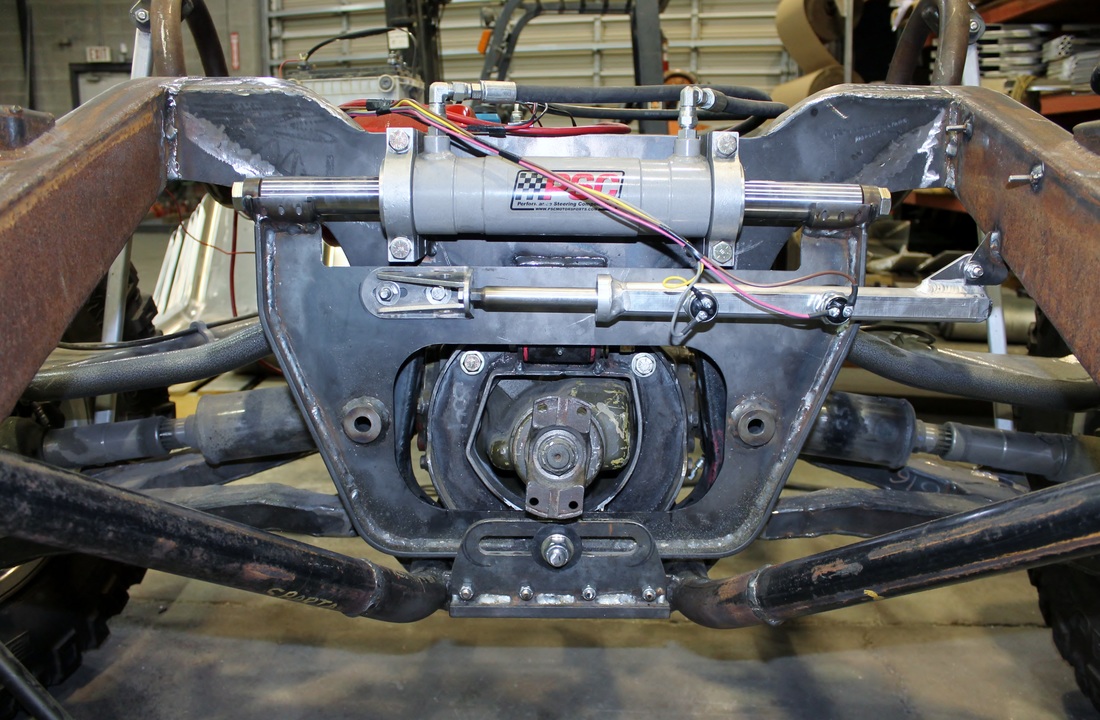

We put so much research and design into our front and rear steering components that we feel they are deserving of their own section in our blog about the ‘Shop Truck’ build. Stemming from our experience on our old ‘Grey Cruiser’ we knew that the steering had to be strong enough to be able to turn over sized tires, with a lot of low end torque pushing through deep snow with independent suspension. Nothing worse than breaking a tie rod end in hip deep snow so we came up with our own custom designed front and rear steering components that a little overkill but seems virtually indestructible. We started with your typical Saginaw power steering pump bolted onto the side of our custom frame. A pitman arm and drag link goes to the custom center tie rod plate which is attached to the frame with 2 over sized swivel joints. These swivel joints hold the center tie rod in place and allow the complete unit to swivel from side to side. Attached to the center tie rod plate are the actual inner and outer tie rod ends. This set up works great, even for dry steering 37” Mickey Thomson tires. The rear steer uses much of the same concept as the front steering components. As you can see we went with a PSC hydraulic steering system that is bolted to either side of the giant center tie rod plate. As the plate is pushed side to side, the inner and outer tie rods push and pull giving us our rear steer which turns independently of the front. Also shown is our self centering ram which is basically an automated ‘on / off’ switch for the hydraulic steering pump based on distance traveled. All components are designed, cut and fabricated in house. Aqualu Industries not only manufactures high quality aluminum bodies and accessories for Jeep, Land Cruiser and Samurai but we are also a full service aluminum fabrication shop with 2 CNC router tables. Definitely helps when designing your own components for custom projects like this. *Disclaimer, Aqualu only builds vehicle for in house abuse, we do not offer build services.* Our build starts with a collection of custom made parts as well as over the counter goodies. As we said in our last blog post, we started with our #4580 FJ45 long box frame which we make in house for our Aluminum bodies. After deciding to use the same military Gamma Goat differentials with 5.70 gears as our ‘Grey Cruiser’ we came up with a whole new diff cradle design to include our independent front and rear suspension. Our custom 1-1/2”, 3/16” wall D.O.M. tubing upper A frames, 10ga. steel lower A frames and Spidertrax unit bearings are more than adequate to keep the 37’s turning and bouncing over any terrain we point them at. For aftermarket goodies we have 13” drilled rotors and double piston calipers from Wilwood. 14” long limiting straps with double shear mounts from TMR Customs based out of Ontario Canada. F-O-A coilover shocks with remote reservoirs will keep our Mickey Thompsons planted. We chose to go with a PSC motorsports steering ram to power the rear steer and after an undisclosed amount of R&D time we managed to make a custom rear steer self centering ram with a lock out pin which works flawlessly. A lot of R&D went into the chassis alone from making custom IFS and IRS factoring in for travel, self centering rear steer to the shock hoops even the brake line retainers are all made in house. Next week we will put in the drive train, fabricating some mounts and hopefully fitting the cab onto the frame. Life's hard, get a helmet! *Disclaimer, Aqualu only builds vehicle for in house abuse, we do not offer build services.* Back in March of 2008, 4 wheeler & off road magazine wrote an article about Aqualu’s Custom built FJ40 made to run with the Kelowna Snow wheelers. This machine was a beast! With front and rear independent suspension, rear steer and Joystick controlled air ride all powered by a supercharged Cadillac 540 big block. It was an aggressive snow hurler that proved itself not only in the snow but in any off road situation as well. The only terrain this monster hasn’t tamed was the street. That sparked the idea for the new build. Make a street-able, big powered, head turning little brother to our already popular ‘Grey Cruiser’. Aqualu Industries builds light weight aluminum replacement bodies for Jeep, Landcruiser and Samurai bodies so naturally our only decision to make was, which one do we want to build? We decided to base this build off of a Toyota Land Cruiser FJ45 long box truck. Something reliable enough you could drive everyday but on weekends could tear up the trails. For reliability, we chose a 6.0litre LQ4 engine and 4L80E automatic transmission out of a 2006 3/4ton Chevrolet truck and an NP205 T-case. To dominate off road we went with the same independent suspension and military Gamma Goat diff’s as our old ‘Grey Cruiser’ except this time the rear steer is self centering. Every week we will be updating our blog with progress updates on our 'Shop Truck' build starting with this picture below, you can see we started with our #4580 1965 - 1978 FJ45 long box frame and we added our own special touches Like one off differential carriers, upper and lower A-arms for the independent suspension as well as the 37" tall Mickey Thomson Baja MTZ's. Check back next week for phase two of project 'Shop Truck'. *Disclaimer, Aqualu only builds vehicle for in house abuse, we do not offer build services.* |

AuthorArchives

January 2017

Categories |

Serving the Off-Road Community since 1989.

Get Updates from Aqualu |

Aqualu Industries Inc.

|

Aqualu Industries Inc. | Content Copyright © 2024

RSS Feed

RSS Feed